NitroVolt enables farmers produce ammonia fertilizer on-site with renewable energy

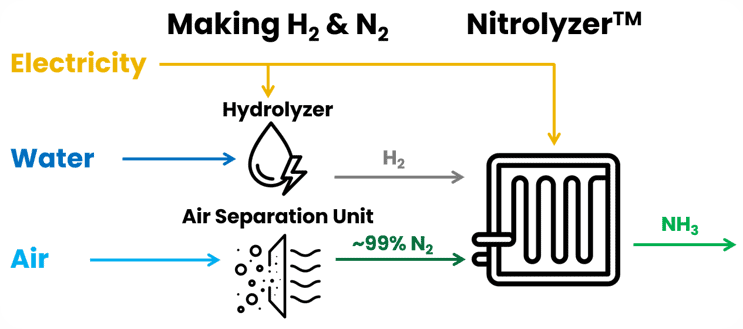

NitroVolt aims to decarbonize nitrogen-based fertilizer production one farm at a time, cut the logistic costs of distributing fertilizer, and make the agricultural sector more resilient to external factors and political issues. Its device offers an eco-friendly solution to traditional ammonia production methods by using a process that splits water into hydrogen and oxygen, combines the hydrogen with nitrogen extracted from the air, and utilizes lithium to catalyze the reaction in a chamber, producing ammonia. This innovative approach could be particularly significant for operations that aims to eliminate carbon emissions.

Historically, ammonia production has relied on the Haber-Bosch process, dependent on natural gas and known for its environmental footprint. Andersen’s technology promises a sustainable alternative, which is important for agricultural sectors in regions like Denmark, where ammonia is not readily produced, forcing farmers to import it from countries such as Poland.

NitroVolt’s system, compact enough to fit in a standard shipping container, is poised for a pilot with a Danish rapeseed farmer and is planned to scale up to produce 150 kilograms of ammonia daily—enough to sustain typical farms in Denmark and the U.S.

The company recently raised a 2.75 million Euro Seed round, supported by entities including BackingMinds, EIFO (the Danish sovereign wealth fund), and other investors like Breakthrough Energy Fellows and the EQT Foundation. These funds will help build the pilot unit and expand the team.

This development comes as more farmers are integrating renewable energy sources like solar and wind into their operations, aligning with NitroVolt’s model of utilizing on-site renewable energy to produce ammonia cost-effectively.

Enjoyed this story?

Every Monday, our subscribers get their hands on a digest of the most trending agriculture news. You can join them too!

Discussion0 comments