EuroChem’s Usolskiy Potash Complex integrates AI technologies

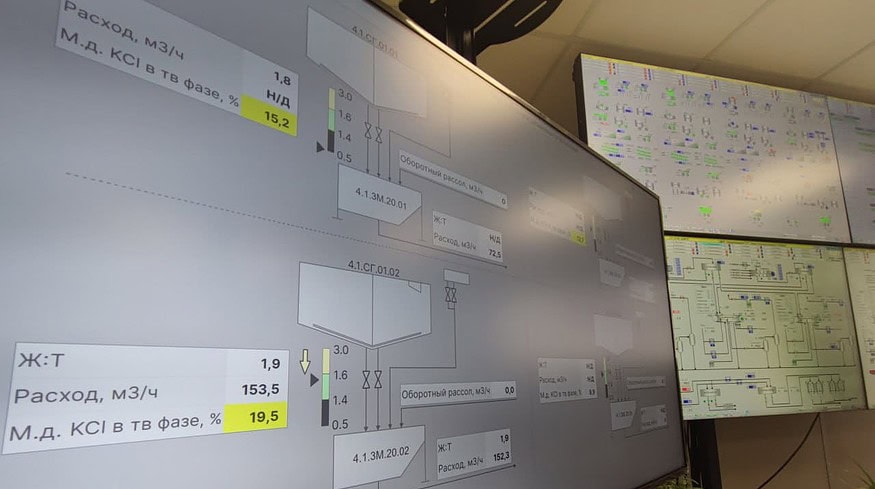

At Usolskiy Potash Complex, a new phase of artificial intelligence (AI) implementation is underway at the flotation beneficiation factory. The AI system assists operators in decision-making by optimizing ore enrichment processes and reducing the risk of errors.

Early in 2024, the plant’s specialists, together with a team from Digital Technologies and Platforms, commenced the experimental industrial operation of AI in areas such as sludge thickening, milling, flotation, and granulation. The system now analyzes data in real-time, offers recommendations for adjusting equipment parameters, and features capabilities for self-learning.

The factory’s chief technologist, Alexander Vaskin, highlighted the recommendation system’s essence: “The system automatically retrieves equipment operating parameters online, analyzes them based on direct and indirect characteristics, and provides the operator with recommendations via a monitor for the most effective management of technological processes and equipment parameter adjustments. Moreover, the system continuously learns from the process.”

For instance, in the drying and granulation department, the recommendation system saves fuel gas, while in the granulation phase, it helps to increase the output of premium products.

A video analytics system also plays a crucial role: it monitors the color of the ore on conveyors, determining the content of insoluble sediment, and assists in tracking increases in potassium and moisture content at the tailings belt filter station.

Enjoyed this story?

Every Monday, our subscribers get their hands on a digest of the most trending agriculture news. You can join them too!

Discussion0 comments