EuroChem completed the project at the Usolskiy potash plant

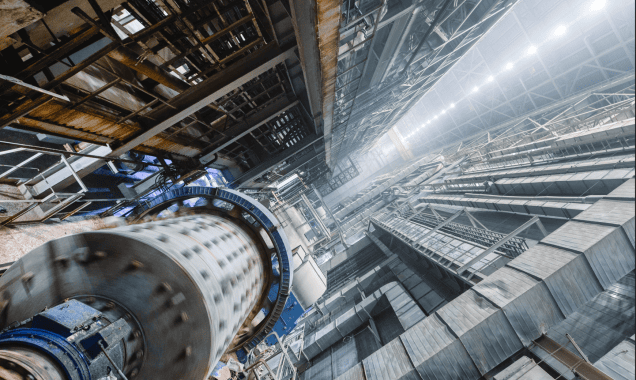

EuroChem has implemented a complex for automation of flow and transport systems, named MS 23.00, at the Usolskiy potash plant in the Perm region. This is the first Russian development based on the principles of end-to-end digital technology. The project was carried out as part of import substitution and allowed the company to get away from the use of imported components and accessories for automated control systems.

The project was implemented with a grant from the Skolkovo Foundation to support the transformation of priority sectors of the economy and the social sphere through the introduction of domestic products, services and platform solutions created on the basis of end-to-end digital technologies.

The project was developed by the Russian company Promtech. A joint team of representatives from EuroChem, the Skolkovo Foundation and the developer company worked on the project.

The new digital platform is an automation system for the underground conveyor transport of the mine. All conveyors of the enterprise are brought into a single digital system. This is an innovative software and hardware complex that solves the problem of digital transformation of the process of managing flow-transport systems. It’s compatible with modern production management systems, and has the ability to integrate with all automation systems for technological and production processes.

According to the statement of Radik Bedretdinov, head of energy and automation at the Mining Division of the EuroChem campaign, MS 23.00 is a completely domestic development. It meets the requirements for the flow-transport control systems and significantly exceeds well-known foreign analogues in its capabilities. The construction architecture allows using MS 23.00 as a fragment of a multi-service data transfer network with the ability to connect various external devices to it, including wireless ones. MS 23.00 fits into the concept of digital transformation of EuroChem’s mining operations.

The implementation of the complex allows you to create production analytics, monitor the implementation of scheduled maintenance, contribute to increasing the level of safety and reducing the accident rate of process equipment.

Currently, work is underway to replicate and expand this system to other enterprises of the company, in particular, to EuroChem-VolgaKaliy in the Volgograd region.

Enjoyed this story?

Every Monday, our subscribers get their hands on a digest of the most trending agriculture news. You can join them too!

Discussion0 comments